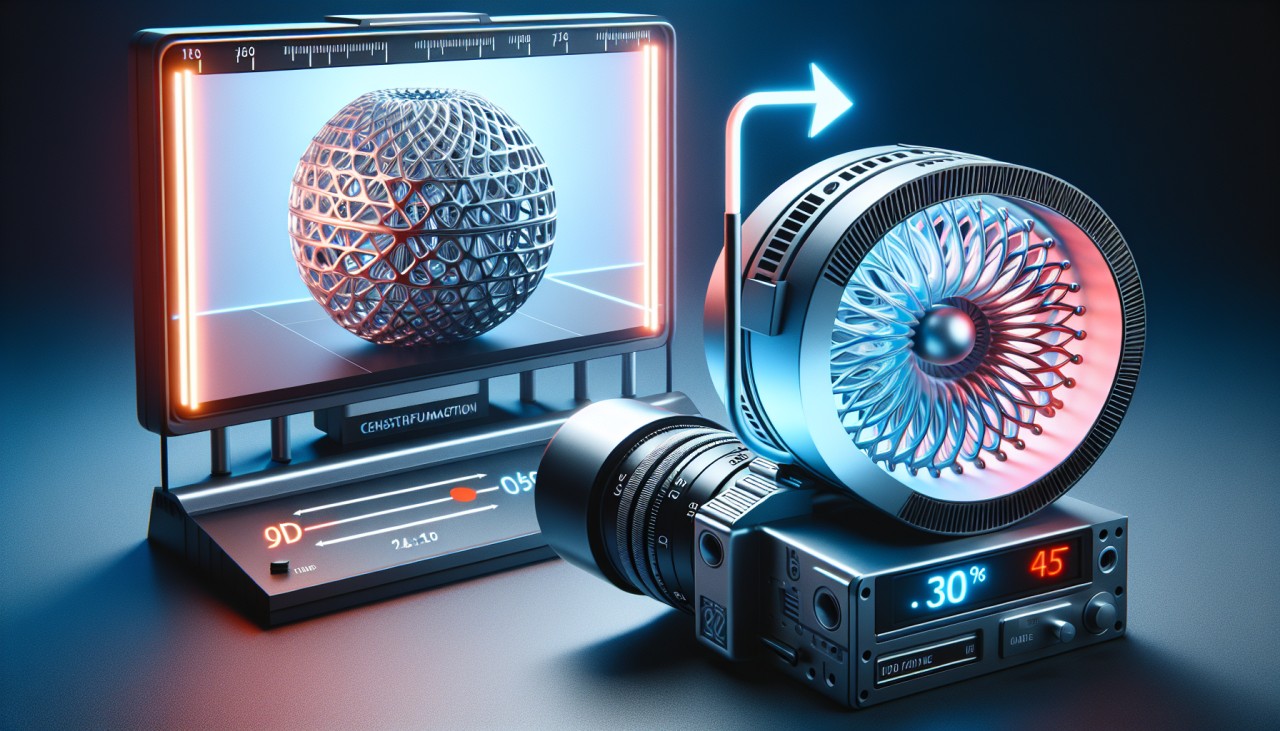

4D printing, an evolution of 3D printing, introduces the dimension of time, enabling materials to transform in response to external stimuli such as heat, light, or moisture. This innovation has led to the development of smart materials that can change shape, stiffness, or functionality over time, opening new possibilities across various industries. In the biomedical field, researchers have created 4D-printed surgical tools that adapt to their environment, enhancing precision and reducing recovery times. For instance, a 4D-printed surgical gripper can adjust its shape and stiffness in response to specific stimuli, allowing it to navigate through tight spaces and manipulate delicate tissues effectively. Similarly, self-expanding stents have been developed to change their diameter based on the patient's needs, ensuring optimal blood flow and reducing the risk of complications. pmc.ncbi.nlm.nih.gov

Beyond healthcare, 4D printing is making significant strides in other sectors. In agriculture, smart irrigation systems utilizing 4D-printed valves can dynamically adjust water flow based on soil moisture levels, promoting efficient water usage and improved crop yields. In the fashion industry, designers are exploring 4D-printed clothing that adapts to environmental conditions and the wearer's movements, offering enhanced comfort and functionality. For example, a 4D-printed dress could dynamically alter its texture or form based on the wearer's movements, resulting in a fluid, ever-changing design. hubs.com These advancements highlight the transformative potential of 4D printing in creating responsive, adaptable materials that can revolutionize product design and functionality across various industries.

Key Takeaways

- 4D printing enables materials to change shape over time in response to external stimuli.

- In healthcare, 4D-printed surgical tools improve precision and reduce recovery times.

- Smart irrigation systems using 4D printing promote efficient water usage in agriculture.

- The fashion industry is exploring 4D-printed clothing that adapts to environmental conditions.

- 4D printing is revolutionizing product design across various sectors.